The Zero Energy Home: Learning to Be the Change

May 19, 2021

Cold Brook Farm: A Year to Remember

April 11, 2023This 12-part blog series will share the vision, architectural challenges, and construction effort involved in building a new house, one that defies conventional home design by integrating the environment in a rigorous, unprecedented and beneficial way.

Based on conversations with Jason D., Homeowner, Cold Brook Farm, and Tom Vierschilling, Project Archietct, RA, LEED AP, WESKetch Architecture + Construction | November 6, 2021

“There is nothing more deceptive than an obvious fact.”

— Arthur Conan Doyle

Fall is one of the prettiest times of year in New Jersey, but changing leaves, harvest moons, and chilly weather remind us that colder days are ahead. Like all homeowners, Deborah and Jason D. had to settle on the type of insulation material for Cold Brook Farm. However, as with so many construction decisions around the zero-energy home, the choice of insulation—seemingly pedestrian—took an unexpected turn.

Insulation is critical to a home’s building envelope—the shell that separates the exterior elements from the interior home. By some estimates, homeowners can save at least 15% per annum on their heating and cooling costs with high-performing insulation, and there is a specific conduction standard, the R-value, which rates insulation based on its capacity to resist heat transfer. In principle, the higher the R-value, the better the insulation performance.

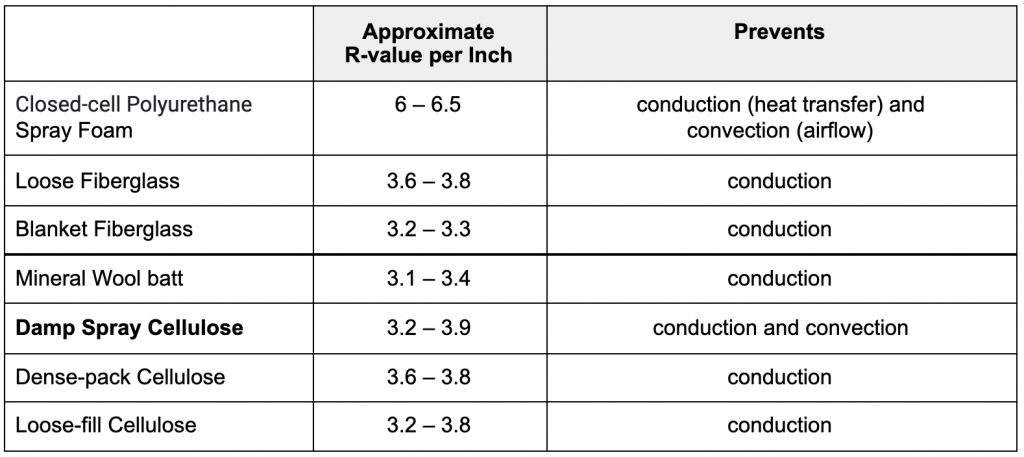

A comparison of R-values, in and of itself, might suggest closed-cell polyurethane spray foam as the obvious insulation choice for Cold Brook Farm. However, in the context of two other essential considerations—safety and environmental-friendliness—a different insulation front-runner quickly emerged.

By the Numbers: Insulation R-Values

Cold Brook Farm was framed with Tstuds, an energy-efficient, innovative lumber-replacement product with an internal truss system. The truss system supports a gap in the outer wall immediately reducing the transmission of hot or cold air from the outside of the home. Within this gap, the builder adds a choice of insulation, but understandably, the stiffness of insulation products like blanket fiberglass, mineral wool batts, and dense-pack cellulose is not particularly compatible with Tstud. Cold air simply moves up the interior of the wall around blankets or batts of insulation. On the other hand, Tstuds do lend themselves to two insulation possibilities: closed-cell polyurethane spray foam or damp-spray cellulose. By the numbers, the choice might appear obvious, but the decision to go with damp-spray cellulose revolved around more than the comparative R-values.

Out-gassing from closed-cell polyurethane spray foam

Given the use of Tstuds in the zero-energy home, one insulation option for Cold Brook Farm was closed-cell polyurethane-based spray foam. Although more expensive than other insulation types, comparatively, it offers the highest R-value per inch and is convenient to apply. Spray foam prevents heat transfer via conduction and also convection, or airflow. This type of insulation is excellent for insulating small nooks and crannies too.

R-values aside, polyurethane foam is manufactured from fossil fuels, creates a great deal of pollution at the point of manufacture, and has a significant embedded carbon footprint. At the time and location of installation, when the two major components of polyurethane foam, isocyanate and polyol resin, are mixed precisely, they become inert. However, if the two components are not mixed in perfect proportion resulting in the components being neither fully reacted nor the application properly cured, there can be continuous out-gassing from the initial installation. Sometimes there is an odor, but often not, so the out-gassing can go undetected and poses negative health effects. Moreover, spray foam is untested over long periods of time, so the impact over 10 to 15 years is relatively unknown.

The attic of Cold Brook Farm covered in loose-fill cellulose insulation and interspersed with walking bridges

Damp-spray cellulose and specialty air-sealing tape

The other insulation option for Cold Brook Farm was cellulose, comprised of 80% recycled paper and 20% borate. In addition to the environmental benefit of recycled paper, the use of borate has many advantages.

It is:

- fire-retardant

- resistant to insects and rodents

- anti-fungal

Cold Brook Farm used all three kinds of cellulose insulation — loose-fill in the attics, dense-packed in the basement/foundation walls and damp-spray in all above-grade, exterior building walls. Similar to closed-cell polyurethane spray foam, damp-spray cellulose insulation prevents both conduction and convection. However, in addition to its recyclable, environmental-friendly composition, damp spray cellulose in combination with adhesive, air-sealing tape prevents heat loss from convection remarkably well.

Cold Brook Farm used all three kinds of cellulose insulation — loose-fill in the attics, dense-packed in the basement/foundation walls and damp-spray in all above-grade, exterior building walls. Similar to closed-cell polyurethane spray foam, damp-spray cellulose insulation prevents both conduction and convection. However, in addition to its recyclable, environmental-friendly composition, damp spray cellulose in combination with adhesive, air-sealing tape prevents heat loss from convection remarkably well.

The tape, part of the Air-Sealing System by Pro Clima and provided by 475 High Performance Building Supply, was used to seal the building envelope of the zero-energy home further underpinning the insulation performance. And, unlike spray foam, cellulose insulation is well-tested and has stood the test of time.

2 Comments

Your blog and your journey are absolutely fascinating and inspiring. Wishing you all a very Happy Holiday season!

I enjoy reading your blogs – so interesting!